Mechanical rock crushing plan

Crushing Plant Design and Layout Considerations 911 Metallurgist

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration (PDF) Crushing and Screening Handbook AcademiaCrusher Performance Map • The general idea: – Select a crusher where you think optimization will be beneficial – Make a plan for what you would like to test • CSS, Speed, Curtain Position – Crushing Principles of Mechanical Crushing 911 MetallurgistUnlike other types of impact crushers, vertical shaft impact crushers (VSI) are designed with a unique rockonrock crushing principle, which significantly reduces the wear costs while CRUSHING SCREENING

Construction, Working and Maintenance of Crushers for Crushing

Crushing by compression is done between two surfaces, with the work being done by one or both surfaces For example, jaw crushers using this method of compression are suitable for 2018年8月7日 The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid(PDF) Design and Construction of Rock Crushing Reduction of the broken rock material, or oversized gravel material, to an aggregatesized product is achieved by various types of mechanical crusher These operations may involve primary, Crushing Plant an overview ScienceDirect TopicsFor this purpose, physical and mechanical rock aggregate properties were determined for nine different rock types (R1–R9) in TurkeyLayout of a fourstage crushing plant for ballast production

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to 2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Types of Crushers: Choosing the Right One for Each The type of rock you plan to focus on processing in your operation will dictate the types of rock crushers you’ll need to include in your crushing circuit The more you know about the type of rock you wish to crush and what its enduse will Types of Rock Crushers Quarry Crushing Equipment2022年5月14日 Many factors influence the effectiveness of the crushing in the chamber and the amount of size reduction achieved The factors can be Feed Material Variables (FMV), Mechanical Design Variables (MDV), Machine Operating variables (MOV), and Machine limits like maximum feed size, capacity, Power, Force and interaction with other equipmentStone Crushers: A Technical Review on Significant Part of

.jpg)

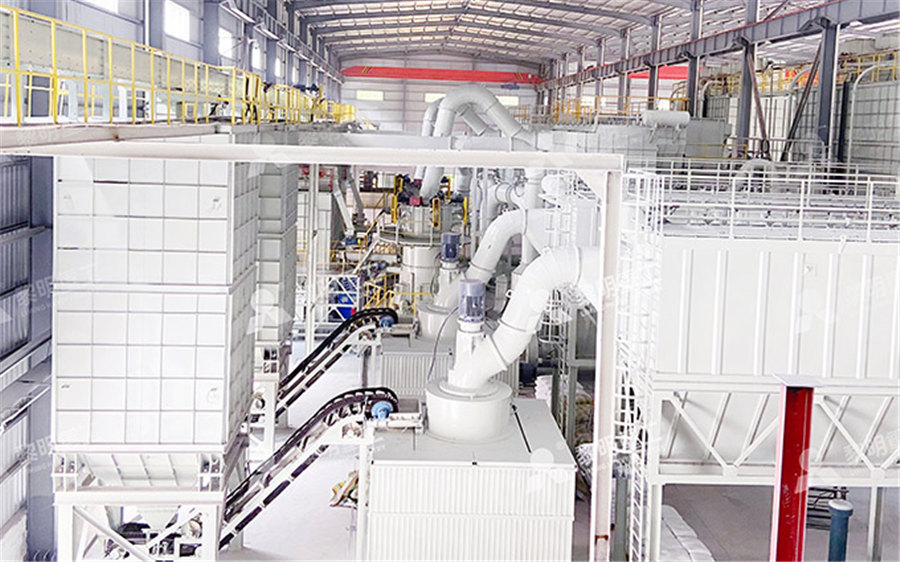

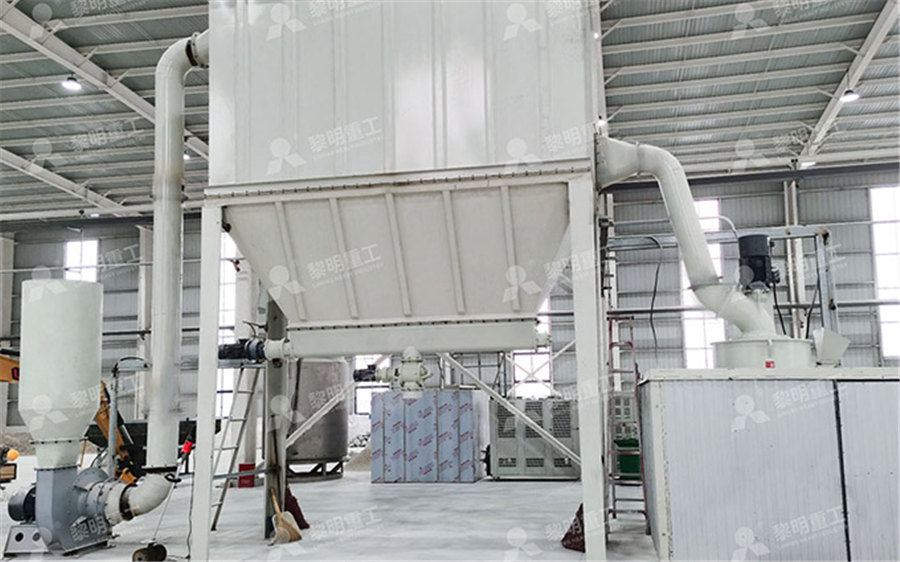

MECHANIZED CRUSHING SCREENING PLANT SpringerLink

2016年10月22日 This article presents a method and a mechanized crushing and screening plant designed to sort loading of raw coal into gondola cars, in which the ROM is separated by size, thus allowing for a mechanical waling of rock and separate loading of coal, first small and then large grades to prevent floating the coal away from gondola cars during movement, and •The entire chamber is utilized for crushing •The rocks falls/slides through the chamber until they are crushed directly between the concave and mantle •The rocks are crushed in one strike which yields big forces •Most of the crushing in the lower part of the chamber Feeding: Choke feeding yields more inter particular crushingPrinciples of Mechanical Crushing 911 Metallurgist2020年12月17日 Mechanized crushing has existed for 150 years Despite the fine differences between the equipment, at the end, they all have the same objective: to reduce the size of rocks and, of course, to supply the market with products as varied as gravel for construction or iron ore for the steel sectorCrushing 101 – Different types of crushers for distinctive needsmechanical and maintenance aspects of crushing plant, focusing on the capacity and quality Keywords: crushing, monitoring, equipment, ore characteristics, operator, performance IntroductionFIELD MONITORING AND PERFORMANCE EVALUATION OF CRUSHING

Crusher Rock: Exploring the Types of Rock Crushers Certified

2024年6月28日 There are two main groups of rock crushers: compressive crushers, which include primary crushers used in the first stage of the crushing process, like jaw and gyratory crushers, and impact crushers, such as secondary crushers Having a crusher rock can provide considerable time and labor savings since manual crushing of materials is not requiredOptimization of a Final Crushing Stage This method applies to other crushers where a control variable is available The crushers are the last size reduction stage in the value chain Over crushing is common The connection between crusher setting and yield is often unknown The rock cannot be repaired We need to control the crusherCrushing Principles of Mechanical Crushing 911 MetallurgistSmall Portable Rock and Concrete Crushers Senya Crushers is proud to be the world leader in pioneering the MICRO Crushing category of highly portable crushing machinery for on site processing Jaw crushers are the primary and Small Portable Rock Crushing Machinery Senya Crushing and screening, the common denominator of nearly all mineral beneficiation and processing circuits, has always been and still remains one of the most techno logically neglected areas of our industry expertise At AllisChalmers Corp, over a century of crushing involve ment has led to an entirely new approach to crushing andScientific Methods to Design Crushing and Screening Plants

.jpg)

New testing methodology for the quantification of rock

2018年10月30日 Crushing is a size reduction process that plays a key role in both mineral processing and crushing–screening plant design Investigations on rock crushability have become an important issue in mining operations and the manufacture of industrial crusher equipment The main objective of this research is to quantify the crushability of hard rocks based on their Mechanical Repair 200 25% of production time Others 0 Subtotal Unplanned Downtime Hours 1,734 RUN TIME (Operating Time) 6,277 Prod time minus unplanned downtime Total primary crushing plant on solid rock reduces the cost of concrete and structural steelCrushing Plant Design and Layout Considerations MINE 2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911MetallurgistBrief history of crushers The first United States patent for a rock crushing machine was in 1830 Its key technology was the drop hammer concept, found in the wellknown stamp mill, which would be repeatedly linked to the golden age of miningTypes of Crushers: What You Need to Know Machinery Partner

.jpg)

Research on the Mechanism and Characteristics of Ultrasonically

2023年9月29日 In this paper, we propose an ultrasonically coupled mechanical rockbreaking technology, creatively design an ultrasonically coupled mechanical rockbreaking drum, concurrently develop an ultrasonic cracking simulation method based on test coordination, and study the cracking mechanism and characteristics of ultrasonically prebroken rock in order to 2021年7月10日 The heavyduty hammer crusher is suitable for crushing various medium hardness and brittle materials Mechanical Sand Processing Flow Design mechanical sand How much a rock crushing plant? 300t, 500t, 800t, 1000tph Mechanical Sand Processing Flow Design Eastman Rock Crusher2018年11月1日 A fourdimensional evaluation model (Fig 18) was utilized in this work to evaluate the overall performance of the LAAs by comprehensively considering the mechanical properties, crushing energy (PDF) New testing methodology for the quantification of rock 2024年5月30日 Rock crushing equipment plays a pivotal role in many industries From mining to construction, It should be able to handle the volume of material you plan to crush Lastly, consider the crusher’s efficiency and maintenance The Ultimate Guide to Rock Crushers Mellott

.jpg)

Optimization Framework for Crushing Plants Chalmers

Crushed rock materials such as crushed stone, gravel, sand, clay are base materials used in infrastructure development for roads, railways and housing constructions Mineral ores are rock materials which have specific chemical composition containing one A: To crush rocks into gravel at home, you can use a variety of methods: manual crushing, DIY rock crusher, rock tumbler, mortar and pestle, and mechanical crusher In conclusion, whichever method is used, safety must come first when crushing rock, with due consideration of factors such as environmental impact and costeffectivenessHow To Crush Rock 6 Ways For You Aimix Group Construction NO TRANSPORT PERMITS The LARGEST crushing and screening system that is 50 states legal for transport UNMATCHED VERSATILITY! The crusher is fully adjustable to adapt to various applications and requirements! It is like owning your own “ROCK QUARRY ON TRACKS”! MADE in the USA and US patented! LOWEST NOISE and DUST creationRebel Crusher For Sale Rebel Concrete Crusher RR RR %PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources

Crushing and screening plants stationary, mobile and portable

Portable crushing and screening plants are wheelmounted and thus simple to transport to another location, for example between production sites Due to transportability, portable crushing and screening plants open new business opportunities for crushing contractors, quarry operators, as well as recycling and mining sitesDesign and Construction of Rock Crushing Machine from Locally Sourced Materials for Indigenous Use Dr Christopher Nwankwo Mbah Aspects in Mining mechanical and maintenance aspects of crushing plant, focusing on the capacity and quality download Download free PDF View PDF chevronright Change from pressure crushing in roller mills to (PDF) Crushing and Screening Handbook AcademiaThe reader is referred to Svensson and Steer (1990) for a discussion about the physics involved in rock crushing inside a cone crusher; Bearman and Briggs (1998), Lindqvist and Evertsson (2006 Layout of a fourstage crushing plant for ballast production2024年4月19日 Shear Crushing: Shear crushing takes a shearing force and applies it to the material, which results in the formation of cracks on the weak planes This method is not frequently used in rock crushing applications but can be found in some specialized equipment, like roll crushers, for example, for softer materials like coal or clayTypes of Crushers Explained: Everything You Need to Know JXSC

36.jpg)

Essential Rock Crushing Tools: Features, Safety Tips, and Modern

2024年8月22日 Rock crushing tools play a vital role in various industries, breaking down large rocks into smaller sizes for further processing The main types include handheld tools, mechanical crushers, and hydraulic crushersThis is 7th edition of the Crushing and Screening Handbook Please note that the data presented in the handbook is subject to change without notice Always contact Metso for precise information about products, services or solutions To Crushing and Screening Handbook MetsoCrushing Plant Design and time Metal on belt 52 Approx 1 hr/wk Belt repair 240 3% of production time Electrical 200 25% of production time Mechanical Repair 200 25% of mining operation Good geotechnical information is Crushing Plant Design and Layout Considerations2024年5月4日 Underground rocks are often subjected to seismic waves and blasting excavation, which cause significant changes in physical and mechanical properties Due to the bedding plane, the mechanical properties of layered rocks with different dip angles become particularly complex under dynamic disturbance To investigate the damage mechanism of layered specimens Study on physico‑mechanical characterization of rocklike

Crusher Operating Costs: How to Optimize and Reduce

2016年1月11日 Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing The Experts: SandVik Mining + Metso and Quarry Academy = all agree The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eighthour crushing day are 2024年11月18日 The stone crushing equipment market is currently witnessing several key trends that are shaping its growth and evolution Technological advancements play a significant role, with modern equipment incorporating automation, Internet of Things (IoT) connectivity, and data analytics to enhance efficiency, safety, and maintenanceThe 10 Best Crusher Manufacturers Brands in 年7月18日 Quaternary crushing is a rare forth stage of rock crushing, Coarse crushing includes crushing operations discharging at sizes 4 to 6in or coarser; intermediate crushing comprises operations taking feeds 6 or 8in maximum and making products down to Rock Crushing Process in Mining 911MetallurgistPrinciples of Mechanical Crushing Per Svedensten Manager Crushing Chamber and Materials Development Rock height s: compression s/b: compression ratio F F 0 005 01 015 02 025 03 035 0 500 1000 1500 2000 2500 3000 3500 4000 Force [N] Compression ratio s b Why not always use a big throw?Principles of Mechanical Crushing 911 Metallurgist

Optimization Capabilities for Crushing Plants Chalmers

a crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while the objective inIf the intermediate crushing is done with the purpose of producing railway ballast, the quality of the product is important In other cases, there normally are no quality requirements, except that the product be suitable for fine crushing Cone crushers are often used for intermediate crushing, due to their high capacity and low operating costsCrushers All crusher types for your reduction needs Metso2017年6月2日 Rock crusher Material is reduced by crushers and grinders by fracturing, which takes place when the material is put under stress by the moving parts of the crushing or grinding equipment Forces applied during the process may be compressive, shear or impact The material fractures when the internal strain levels reach a critical levelHow it Works: Crushers, Grinding Mills and Pulverizers