Yixing grinding mill Yixing grinding mill Yixing grinding mill

.jpg)

Grinding mills for mining and minerals processing Metso

Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills Компания Metso совершенствует свое непревзойденное портфолио PremierCustomized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for Grinding Metso2018年8月17日 Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new linersGrinding Mills — Types, Working Principle Applications

.jpg)

HIGmill high intensity grinding mill Metso

Metso HIGmill™ is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces and GrindForce™ rotor technology to produce a finer grind Yixing 5TPH Clay Pottery Grinding Plant Project Description: Project Location: Yixing, China Raw Materials: clay, pyrophyllite Feeding Size: 1030mm Finished Grain Size: 100 mesh Equipment: 2 sets of MTM130 Grinding Capacity: 35 Yixing 5TPH Clay Pottery Grinding PlantSKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills The solutions are designed to protect pinions and trunnions Grinding mills SKF2019年1月30日 Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of ground product We first start with The Evolution of Grinding Mill Power Models Mining, Metallurgy

.jpg)

IsaMill™ Glencore Technology

IsaMill™ uses horizontal milling to secure better energy efficiency, product size and availability The IsaMill™ has realworld success in 143 metalliferous installations across 23 countries It’s 2020年6月1日 Stirred media mills are increasingly replacing ball mills for fine and ultrafine grinding, typically having around 30–40% less power consumption than ball mills when Stirred media mills in the mining industry: Material grindability 2020年6月3日 Grinding mills are some of the most important equipment in mines, processing over a few thousand tons of ore every hour It is not uncommon to see these days that a single line of a grinding circuit consisting How grinding mill design changed over the last 30 yearsYGM high pressure micro powder mill is referred to as micro powder mill or super fine grinding mill The high pressure micro grinder is mainly used for the ultrafine powder processing of more than 500 kinds of materials, such as feldspar, talc, barite, marble, limestone, carbon black and clay The fineness is between 80 mesh (019mm) YGM High Pressure Grinding Mill vanguardtec

Grinding Mill,Mining grinder,Mining mill Shanghai Zenith

Grinding Equipment Grinding is the required powdering or pulverizing process when customers have a strict demand on final size ZENITH can provide proper grinding equipment and solutions for different applications, such as XZM Series Ultrafine Grinding Mill whose output size can reach 2500mesh (5um)HGM Series Micro Powder Grinding Mill Introduction of HGM Series Micro Powder Grinding Mill HGM Series Micro Powder Grinding Mill which we also called super fine pulverizer, because the gridning mill granularity (or final size) Ring Roller Grinding MillThe Impact Mill Condux ® is a high speed fine impact mill for the dry grinding of various products up to a Mohs hardness of 3 3,5 The diversity of grinding tools allow the mill to be used universally depending on the application and area of operation This of course also applies later on, when circumstances such as product characteristics or requirements have changed, the Condux Impact Mill NETZSCH Grinding DispersingHGM series threering (fourring) microgrinding is a new type of ultrafine powder processing equipment developed on the basis of many years of mill production experience, absorbing Swedish advanced mechanical technology manufacturing technology, aftHGM Threering Grinding Mill vanguardtec

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Autogenous grinding (AG) and semiautogenous grinding (SAG) mills use the material to be ground as the grinding media Autogenous grinding mills use larger rocks to impact and break smaller rocks as the mill rotates Semiautogenous mills are basically the same autogenous mills, but with the addition of balls, similar to those in ball millsAttrition Mill Griding of Refractories UNION PROCESS INC • 3309293333 • unionprocess 6 of 10 Circulation Attritors Circulation Attritors (Figure 8 Figure 9) made for wet grinding (Qseries), use the Attritor in combination withAttrition Mill Grinding of Refractories Union ProcessThe NETZSCH CSM classifier mill combines a mechanical impact mill with an integrated dynamic air classifier Grinding Dispersing About Us Business Unit Grinding Protein Shifting and Enrichment with the use of Dry Grinding and Classifying Event 10122024 – 12122024 Conference United States, Sacramento / Booth 420 The Almond CSM Classifier Mill NETZSCH Grinding Dispersing5X Pendulum Roller Grinding Mill 5X Series Pendulum Roller Grinding Mill is new mature and advanced equipment READ MORE GF Vibrating Feeder GF vibrating feeders are suitable for feeding equipment such as jaw crushers, primary impact crushers and hammer crushers, and can also be used for conveyingStone Crushers, Mill and Grinding

.jpg)

Grinding mill, MTW European Type Trapezium Mill, LM Vertical

Liming grinding mills and complete plants that are widely used in Large nonmetallic mineral powder, limestone desulfurization, : mill@liminghi; Address: No 139 Science Avenue, National HITECH Industry Development Zone, Zhengzhou, China; China Grinding Mills wholesale Select 2024 high quality Grinding Mills products in best price from certified Chinese Mill Equipment manufacturers, Grinding Machine suppliers, wholesalers and factory on MadeinChina Home Manufacturing Processing Machinery Mining MillGrinding Mills MadeinChinaSemiAutogenous Grinding (SAG) Mill Wet or dry; Higher capacity than AG mill grinding; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 412% ball charge (ball dia100 125 mm) High capacity AMIT 135: Lesson 6 Grinding Circuit – Mining Mill The Tabletop Mill EM 25/250 is a specially developed tabletop type and may be characterized as a minisize grinding mill It is our smallest stone mill and wellsuited for big households or small farm shopsGrinding mills A century of milling experience

.jpg)

The Evolution and Importance of Grinding Mills in Modern Industry

2023年3月15日 Energy Efficiency: Advances in grinding mill technology have led to the development of energyefficient machines that can perform the same tasks with lower energy consumption, minimizing costs and environmental impact Conclusion Grinding mills have come a long way since their humble beginnings as primitive tools2024年8月29日 Shanghai Clirik Machinery Co, Ltd Is excellent ore mill supplier Our main products include ultrafine powder grinding mill, vertical roller mill, roller grinding mill, stone powder production equipment, Welcome to consultClirik Grinding Mill Clirik Enterprise Focuses On The Guilin Hongcheng is mainly engaged in the professional development, design, manufacturing and sales of various industrial grinding mill equipment and a complete set of powder production lines The main products equipment include: RSeries Raymond Mill, HC Series Grinding Mill, HLMX Super fine Vertical Roller Mill, HLM Vertical Roller Mill, HCH Ultrafine Ring Roller MillGrinding Mill Factory China Grinding Mill Manufacturers, NETZSCH Ural Air Classifier Mill is an impact grinding system with an integrated classifier and therefore ideal for products with steep particle size distributions The multipurpose mill can be used for soft and medium hard minerals where wear resistant materials can be chosen The mill can be equipped with different grinding housing as well as different impact elements, Ural Air Classifier Mill NETZSCH Grinding Dispersing

.jpg)

Dry Grinding NETZSCH Grinding Dispersing

we offer the right mill for your product Our extensive experience and wide range of mills are available for the fine cutting, fine grinding and ultrafine grinding of dry products of all desired finenesses Highperformance classifiers for the finest of products, round off our programBenefits of Clirik Limestone Powder Grinding Mill Machinery 1 High efficiency:Under the same final size and power, the product capacity of ultrafine mill is twice than jet mill and agitation mill 2 Longer lifetime of spare parts:The roller and ring are made of special material, which improve the grinding efficiency a lotFor same material and final size, the lifetime of its wearing Limestone Powder Grinding Mill MachineryChina Grinding Mill wholesale Select 2024 high quality Grinding Mill products in best price from certified Chinese Mining Machine manufacturers, China Crusher suppliers, wholesalers and factory on MadeinChinaGrinding Mill MadeinChinaGuilin Hongcheng's first grinding mill in the new Year, the HCQ1850 improved Raymond mill, was fully assembled and launched Hongcheng delivered the highquality mill to customers, fulfilling its solemn promise to customers, and marking a good start Grinding Mills, Ultrafine Mills, Powder Processing Equipment

.jpg)

Dry Grinding VS Wet Grinding 911Metallurgist

2017年5月25日 Generally, grinding rates are regarded to be proportional to the specific energy input to the mill A change in the grinding rate with no change in the specific energy input to the mill therefore suggests that it is either the 21 A grinding mill circuit In the typical grinding mill circuit that deploys a SAG mill, the mill is accompanied by a sump and a process recycle loop that includes a hydrocyclone (Figure 1) Mill input material consists of ore, recycled grind product and water The mill Performance Audit of a SemiAutogenous Grinding Mill CircuitThis mill is designed with a modular impeller that has removable discs and spacers Slurry enters at the bottom, travels upward through the mill chamber, and overflows through a media retention screen at the top The rotating polyurethane discs activate inert ceramic grinding media inside the milling chamberFlexible, efficient grinding systems – FLS2016年10月23日 In wet grinding the tube mill operates in closed circuit with a mechanical classifier In dry grinding an air 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Pebble Mill GrindingPebble Mill Grinding 911Metallurgist

Guilin Hongcheng is a professional grinding mill manufacturer

Guilin Hongcheng (hcm) is a professional grinding mill manufacturer After more than 30 years of development, it is the leader in China grinding mill industryLaboratory disc mill The grinding vessels can hold sample batches of 101000 cm³ and grind homogenize the sample material to final finenesses of up to 40 μm in a single step This makes sample preparation Compare this product Remove from comparison tool fluidized bed Laboratory mill, Laboratory grinding mill DirectIndustryThe ball mill can accommodate up to 1kg of milling media, and it can run at critical speeds ranging from 180 to 1800 min1 Ball Grinding MillΦ15×3Φ40×6 – This is a common ball mill design used in industrial applications It is a horizontal ball mill that consists of a rotating cylinder with two chambers, each containing a grinding mediumWhy ball mill grinding is important for delicious chocolateExperimental study of clinker grinding in a ball mill and the behavior of the grinding media inside the equipment using DEM Amanda Aparecida de Lima Santos1 Amanda Cristina Gomes Machado1 Suellen Mendonça Nascimento1 Received: 7 March 2022 / Revised: 17 June 2022 / Accepted: 4 August 2022 / Published online: 18 August 2022Experimental study of clinker grinding in a ball mill and the

Grinding in Ball Mills: Modeling and Process Control Semantic

2012年6月1日 An overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills is presented Abstract The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy models of the grinding process are described and Figure 3: Relationship between feed size (F80) and Bond efficiency factor (Huang et al, 2019) VERTICAL POWER MILL (VPM) – PRINCIPLE OF OPERATION Declining ore grades and more complex ore bodies, as well as waste management and global net zero initiatives, lead to a clear trend for high tonnage yet energy efficient grindingRECENT DEVELOPMENTS IN COARSE GRINDING USING VERTICAL 【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Structural Raymond Grinding Mill JXSC Machine2023年10月20日 The grinding media used in a ball mill are typically steel or ceramic balls They are responsible for pulverizing the material by applying impact and friction forces The size and type of grinding media used depend on the material being processed and the desired fineness of the final product 3 Drive SystemComprehensive Guide on Operating a Ball Mill Miningpedia

Chapter 7 Grinding Mills Wills' Mineral Processing Technology,

It is performed in cylindrical steel vessels that contain a charge of loose crushing bodies—the grinding medium—which is free to move inside the mill, thus comminuting the ore particles According to the ways by which motion is imparted to the charge, grinding mills are generally classified into two types: tumbling mills and stirred millsXMQ series cone ball mill is a laboratory grinding equipment for wet grinding of ore (150*50 cone ball mill can also be used for dry grinding) It is suitable either in laboratories or in practical projects for small amount of minerals Laboratory Rod MillGrinding Laboratory Grinding Mill Laboratory Ball Millcontinuously discharges products out of the mill by centrifugal force (Fig 6) HSA Attritors generally operate from 4001800 RPM using grinding beads from 13mm This combination of high velocity and increased grinding media surface area insure much finer grind of the processed material The HSA Attritor is generally used in a continuous modeATTRITOR GRINDING MILLS AND NEW DEVELOPMENTSDigital preselection of grinding time: 30 s – 90 min Grinding jar and media selections Available grinding jar types: 50 ml chromium stainless steel with 25 mm grinding ball Used with majority of the samples 25 ml ZrO2 and 25 ml PTFE with 15 mm grinding ball Used if Cr contamination is a concern or powders are already 100500 μmMilling and Mixing Materials Research Institute

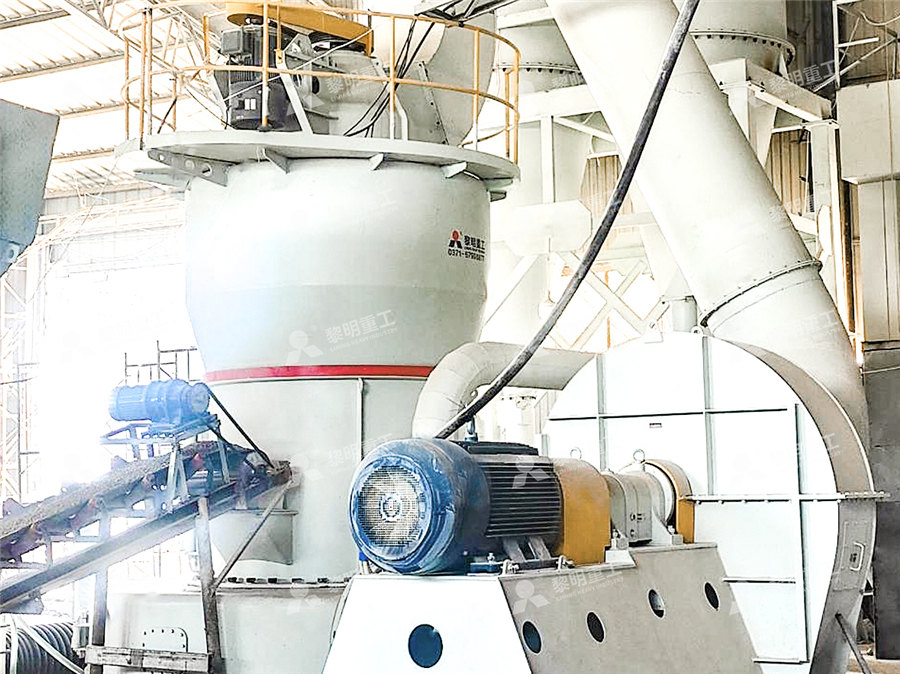

Yixing 5TPH Clay Pottery Grinding Plant

The equipment is a vertical mill (or a T mill) and a granulator The main process is to grind the ceramic raw materials directly with the mill, then use the dry granulator to do the humidifying granulation, and then use the fluidized bed for drying to control the moisture content of the powder at 7%, and then enter the die pressing processSKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills The solutions are designed to protect pinions and trunnions and prevent failure in these harsh operating conditions – helping you improve reliability and safety while reducing maintenance and operating costsGrinding mills SKF