Coal mine limestone grinding production line

active lime production line CHAENG

CHAENG can undertake the 2001500t/d active lime production line EPC, including the the reach report, civil engineering, designing, equipment, installation and debugging "turnkey” service with production capacity and standard achievedProduct: Limestone grinding mill Diameter: Φ15~Φ 42 m Production Capacity: 20300t/d Handle Material: Cement, limestone, slag, steel slag, coal, coal ash, and various mineral oresLimestone Grinder Limestone Grinding Limestone Grinding MillLime Production Line Processing capacity: 300 t/d3000 t/d Output: 500t/d, 700t/d, 100t/d, 1500t/d, 2500t/d Applied materials: limestone, clay, iron ore, coal,etc : sales@shibochinaLime Production Line Zhengzhou Shibo Machinery The production process of active lime is: First, quarrying: the natural limestone is crushed and screened into small pieces suitable for firing One pass is coarse crushing, medium crushing, Lime production line mining processing machine XKJ Group

.jpg)

Limestone mill, Limestone grinding mill All

coal power production line, those metal and nonmetal mines Suitable material: Raw material, clinker, slag, iron ore, limestone, coal powder, coke, coal gangue, fly ash, gypsum, calcite, pyrophylite, quartz, clay, any type of dry The 20TH limestone desulfurization grinding production line is designed to process limestone into a fine powder, which is then used in the flue gas desulfurization (FGD) process This The 20TH limestone desulfurization grinding production line in a 2021年9月15日 This paper reports on results from detailed studies on coal ash and limestone interactions during calcination Industrially produced quicklime from a coalfired rotary kiln was Coal ash and limestone interactions in quicklime productionIn the cement production line, producing 1 ton of Cement need to grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials, and gypsum) Grinding operation consumes about 60% of total power in cement Cement Production Line CHAENG

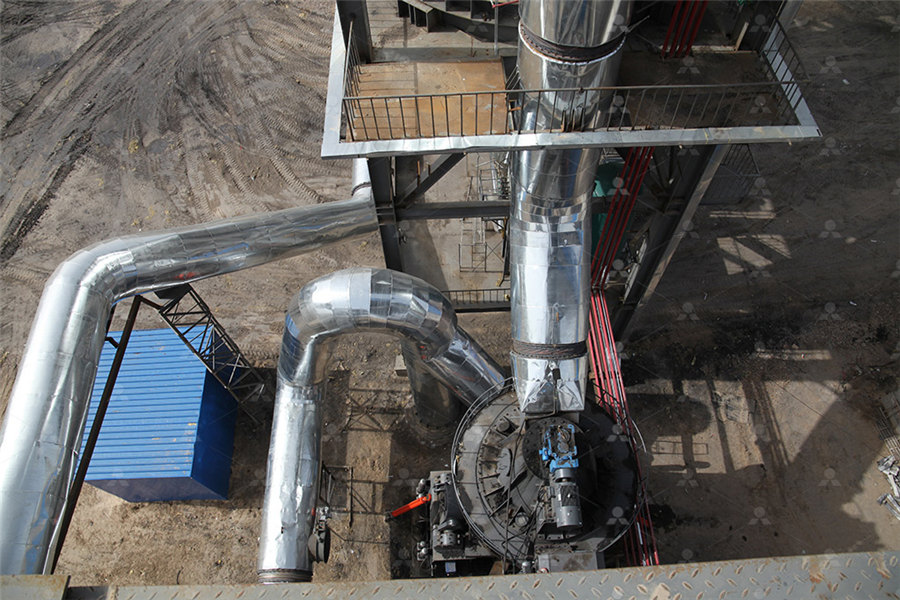

Limestone crushing and screening production line introduction

2024年1月23日 Today, we will focus on the limestone crushing and screening process: Initially, the raw limestone blocks are uniformly conveyed to a jaw crusher through a vibrating feeder Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in origin as is the case with travertineLimestone Quarrying and Processing: A LifeCycle Inventory2024年2月22日 550TPH Granite Aggregates Production Line in Henan; 450TPH Limestone Gravel Production Line in Mexico; 300TPH Feldspar Gravel and Sand Production Line in Gansu; 200TPH Basalt Aggregate Production Line in Sri Lanka; 300TPH Coal Gangue Crushing Production Line in Colombia; 180TPH Waste Rock Crushing Production Line in AustraliaImpact crusher used in limestone aggregate making production line2023年10月8日 Each coal crusher can be combined with the screening equipment (such as vibrating screen) and loaded on the mobile crusher to form an efficient coal crushing and screening production line Capacity: 1700 t/h 6 Types of Coal Crusher: Which Is Best for Crushing My

Limestone crushing and grinding production line SBM

2022年4月20日 Or further grinding to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical industry and other industries Limestone crushing and grinding production line 20/04/2022 admin Limestone PropertiesThe cement production line includes crushing and prehomogenization, raw material preparation homogenization, preheating decomposition, cement clinker sintering, cement grinding, and packaging, etc 1 Crushing and Pre blending limestone, clay, iron ore, coal, etc Limestone is the largest amount of raw materials in cement productionCement Production Line CHAENGThe 20TH Limestone Desulfurization Grinding Production Line: 1 Overview: The 20TH limestone desulfurization grinding production line is designed to process limestone into a fine powder, which is then used in the flue gas desulfurization (FGD) process This production line is capable of handling 20 tons of limestone per hour, making it suitable The 20TH limestone desulfurization grinding production line in a coal CHAENG can undertake the 2001500t/d active lime production line EPC, including the the reach report, civil engineering, designing, Limestone Grinding Line; Nickel Slag Grinding Plant; Steel Slag Grinding Plant; Clinker Grinding Unit; φ24×475m coal mill, 5000 m² bag type dust collector And all of these equipment were made by active lime production line CHAENG

.jpg)

Longterm groundwater geochemical evolution induced by coal

2023年8月11日 Groundwater chemical composition can be changed due to longterm coal mining activities, but it was unclear how it was induced in Taiyuan Formation limestone (TFL) regarding the lack of relevant quantitative studies The aim of this research is to improve understanding of the chemical composition changes in groundwater of L4 limestone in the coal Grinding media are essential components of coal grinding mills, as they are responsible for crushing and grinding the coal material into small particles Grinding media can be made of various materials, including steel balls, ceramic balls, and cylpebs, depending on the specific application and grinding requirementsWhat is a Coal Grinding Mill2023年12月6日 Advantages of HGM series ultrafine grinding production line Focus on high production capacity and output requirements (1) PLC intelligent frequency conversion control cabinet is fully controlled, and intelligent frequency regulation ensures continuous 24 Limestone ultrafine grinding production line customer siteLimestone Grinding Line Materials: Calcium carbonate, limestone, barite, heavy calcium carbonate, etc Capacity: 300,0001,000,000 t/a CHAENG has manufactured many coal vertical grinding equipment which have been adopted by a number of Chinese coal grinding production linescoal grinding machine CHAENG

Production Line Limestone Grinding Equipment Coal Gangue

Production Line Limestone Grinding Equipment Coal Gangue Rotary Mill, Home Manufacturing Processing Machinery Mining Machinery Mining Mill Coal Ball Mill; Production Line Limestone Grinding Equipment Coal Gangue Rotary Mill US$12,00000 14 Sets US$11,00000 5+ Sets Product Details Customization: Available: Type: Ball Mill:2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other Limestone crushing, sand making and grinding processThe Materials Configuration of Lime Production Line: limestone, clay, iron ore, coal,etc Limestone is the largest amount of raw materials in cement production After mining, the size of limestone is large with high hardness, so the limestone crushing plays a more important role in cement plant The Basic Introduction to Lime Production LineLime Production Line Zhengzhou Shibo Machinery 2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller Limestone Grinding Mill That You Need To Know Mortar Plant

.jpg)

6 Cement Equipment For Dryprocess Cement Production Line

2023年12月26日 As we all know, the dryprocess cement production line is commonly used in the cement industry The new type of dryprocess cement production process includes four main sections: Prehomogenization of raw materials, homogenization of raw materials, clinker firing, cement grinding, etc Raw material conveying system The raw material, including limestone, Recently, a mine owner from Sudan contacted the Nile for a list of the configuration of a limestone crushing production line with a capacity of 600 tons per hour After understanding the customer’s needs, our technicians immediately carried out the location of the customer’s production site, weather conditions, and specific stone conditions600 t/h limestone crushed stone production lineAdvantages of limestone grinding mill production line Strong complete set: SBM is an excellent manufacturer of mine milling equipment in China All grinding mills are directly supplied by the factory and there is no middleman, so the cost performance is extremely highLimestone Ultrafine Grinding MillIts production process is as follows: Block degree ≤ 25mm coal, from bucket elevator into the belt, then conveyed to coal bunker by belt, through disc feeder or electromagnetic vibration feeder that under coal bunker,the mill is a set of grinding, drying,when grinding, introducing hot air from rotary kiln system or flue gas from auxiliary combustion chamber to dryGas with coalcome out from 600 tons of active lime production line equipment

Limestone Grinding Mill Plant TAYMACHINERY

The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing 2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and Limestone crushing technology and equipment SBM Raw meal system includes limestone crushing section, prehomogenization storage shed, raw meal grinding mill raw meal silo, etc Burning system includes kiln inlet section, kiln section and kiln outlet section; coal powder production section if coal is used as fuel Cement production system: clinker silos, cement grinding mill section, etc Finished product transporation Cement Production Line, Cement machinery, Rotary kiln, Cement Limestone crushing production line is a type of production line used to process limestone into crushed stone and sand The production line is designed to handle the entire process, from feeding the raw materials to packaging the final prod Limestone crushing production line NEWS SMMVIK Machinery

Cement Production Line

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials, gypsum)Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%Coal mine; Slag; Construction waste; Area In Asia; In Africa; In Europe; In South America; In North America; Capacity Less than 100T/H; 100200TPH; 200300TPH; 300400TPH; 400500TPH; More than 500T/H; Solutions stone line topic Details of limestone gravel production line with 500550 tons per hour; Details of granite gravel production Limestone Crusherlimestone Crushing Production Line2023年6月19日 The coal shall be ground finely in a vertical mill The output of coal mill is 20 tons per hour with a fineness of 10~12% residue on a 90μm sieve Coal will be fed to a vertical mill by a weighing feeder Drying heat source for coal mill will be from clinker cooler2000T/D Cement Production Line GHANA YingYong MachineryLimestone mining plant is used for quarrying and processing limestone for rough block for construction building or dressed stone in various applications including curbing, paneling, veneer, and tile In stone quarry, production of limestone aggregate from surface quarries will undoubtedly remain the principal method of miningLimestone mining equipment for quarrying process

CaseIndustrial Grinding Mill, Ultrafine Grinding Mill, Vertical Roller

From the coal powder preparation, heavy calcium and slag powder processing, to largescale nonmetallic mineral powder, power plant environmental desulfurization, limestone powder, building materials, chemical industry grinding engineering, professional technology covers the whole process chain of mineral processing, product processing range covers 03mm coarse 2024年1月28日 550TPH Granite Aggregates Production Line in Henan; 450TPH Limestone Gravel Production Line in Mexico; 300TPH Feldspar Gravel and Sand Production Line in Gansu; 200TPH Basalt Aggregate Production Line in Sri Lanka; 300TPH Coal Gangue Crushing Production Line in Colombia; 180TPH Waste Rock Crushing Production Line in AustraliaHow to build a high quality granite aggregate production line2024年2月23日 The production of limestone powder involves a series of carefully controlled steps to transform raw limestone into a versatile and valuable material Crushing and Grinding: The extracted limestone is then transported to crushers where it is broken down into smaller pieces 300TPH Coal Gangue Crushing Production Line in Colombia;Introduction of limestone powder making process and applicationProcess introduction GRMC coal vertical mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screenCOAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd

Limestone Grinding Mill Solution Adjustable Powder Fineness

Vertical Limestone Grinding Mill; Production Capacity: 15100t/h: 8176t/h: 50250t/h: Feeding Size: ≤25mm: ≤15≤30mm: ≤1100mm: Application: limestone, cement clinker, gypsum, slag , ore, etc Calcination, gypsum, nonmetallic ore and coal, desulfurizing work in power plant: limestone Lime Production Line Small Scale Lime 2024年2月21日 550TPH Granite Aggregates Production Line in Henan; 450TPH Limestone Gravel Production Line in Mexico; 300TPH Feldspar Gravel and Sand Production Line in Gansu; 200TPH Basalt Aggregate Production Line in Sri The process of limestone aggregate making2024年2月1日 This grinding mill perfectly satisfies the production demands of the customers on 20033μm (80425Mesh) fine powderhttps: 60TH limestone grinding production line YouTube2020年2月18日 Our objectives were: Firstly, to analyze guidelines for the Impact Assessments of NonCoal Mining projects and recommend sustainable strategies; and secondly, to discern the effects of limestone (PDF) Environmental Hazards of Limestone Mining and

.jpg)

Lime Production Process and Required Equipment

2023年2月15日 The industrial production line of lime The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are not suitable for putting in a kiln2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s energy budget Overall Energy Use of Fine Grinding in Mineral ProcessingThis article describes the basics of setting up production lines, how to read the UI of buildings (such as input and output item rates), and how to calculate building ratios For more information on planning a production line, see Tutorial:Production line design tips A simple production line involves Miner → Smelter → Constructor → Storage Container The example shows the Tutorial:Production line Official Satisfactory WikiHot Products PE Jaw Crusher PYS Series Symons Cone Crusher PF Impact Crusher DPC Hammer CrusherProduction Line, Crushing Industry, Sand Stone Crushing Plant

Lime Production Line Active Lime Production Line Cement Plant

SOLUTION2: Lime Production Line With Vertical Kiln The vertical lime kiln is suitable for smallcapacity active lime production lines, lowcost, safe and environmentally friendly The vertical lime kiln uses the principle that the material’s own weight descends and the hot gas rises for heat exchange to burn lime We supply twin shaft lime kiln, double beam lime kiln, annular lime kiln