What quota is used for stone grinding machine to break the road

Rock Crushers Pulverizers Williams Crusher

A rock crusher is used to break down rocks into smaller pieces You can crush the rock into pieces that are your desired product size Rock crushers are most often used for gravel, sand, cement, mining, construction/demolition waste (such as concrete and 展开2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder Crushers Types of Crushers: Choosing the Right One for Each Stage2024年10月14日 What machines are required for a stone crusher plant, and what is the function of each? Here, you'll discover 11 stone crushing equipment needed for stone crushing, from What Machines Do Stone Crushing Plants Need? Fote Machinery2024年11月19日 A stone crusher is a type of pulverizer that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size7 Types of Stone Crusher and How to Choose the Best?

.jpg)

Types of Rock Crushers Quarry Crushing Equipment Kemper

Impactstyle crushers include VSIs, as well as horizontal shaft impactors (HSIs), and are best used with less abrasive rock types, like limestone These types of machines break apart All in all an industrial mill used for grinding whole grain break after a roller mill Cap Kg/h (fine/coarse): 250 800 why grindmaster 950? The Grindmaster model is available in 3 Grindmaster 950 Perfect for professional Grinding Engsko2022年5月14日 Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones It normally highlights a huge crushing rate and high return Stone Crushers: A Technical Review on Significant Part of2017年6月2日 Autogenous grinding (AG) and semiautogenous grinding (SAG) mills use the material to be ground as the grinding media Autogenous grinding mills use larger rocks to How it Works: Crushers, Grinding Mills and Pulverizers

.jpg)

Grinding Mills and Their Types – IspatGuru

2015年4月9日 Grinding mills are size reductions machines that often follow crushers in the processes where finer products are desired after crushing Different grinding machines are 2019年6月17日 Harder than standard aluminum oxide with a very sharp abrasive grain, it is often used for grinding gray iron, chilled iron, brass, soft bronze and aluminum, as well as stone, rubber and other nonferrous Selecting the Right Grinding Wheel for Your ApplicationA grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool Each grain of abrasive on the wheel’s surface cuts a small chip from the workpiece via shear deformationWhat Is Grinding Machine? Definition, and Types The 2000年12月15日 Make grinding contact gently, without bumping or gouging Never force grinding so that the motor slows noticeably or the work gets hot The machine ampmeter can be a good indicator of correct performance If a wheel Choosing The Right Grinding Wheel Modern

Types of Crushers: What You Need to Know Machinery Partner

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust Crushers are mainly used in the mining and construction industries, where they are used to break down very large rocks and boulders into smaller pieces Crushers are also commonly used for jobs like breaking up asphalt for roadwork or demolition projects2024年3月13日 Surface Grinding: Used to produce a smooth finish on flat surfaces, surface grinding machines use abrasive wheels rotating at high speeds Cylindrical Grinding : Involves grinding the outside diameter of a cylindrical workpiece, used in What is Grinding Machines: Different Types, Uses, and Price2020年9月7日 The progress of processing powder size is called grinding The final powder size can reach from 05 mm to 0005 mm There are also several grinding mill machine: Raymond mill, High pressure grinding mill, and Micro powder grinding mill etc However, in most case, a small crusher is needed in the grinding mill machineWhat is the difference between crushing and grinding?Ploughing in particular can break or cut stones Grinding stones are unmistakable Aboriginal artefacts, and many have been collected as souvenirs Flat stones have even been used for dry stone walls, paths and house foundations Once the stones are moved, important information about them is lostFact sheet: Aboriginal grinding stones

.jpg)

Chapter 16: Grinding Wheels and Operations American Machinist

2020年6月29日 Wheel speeds are measured in surface feet per minute (SFPM) Vitrified bonds are commonly used to 6,500 SFPM or in selected operations up to 12,000 SFPM Resinoidbonded wheels may be used for speeds up to 16,500 SFPM Grinding pressure Grinding pressure is the rate of infeed used during a grinding operation; it affects the grade of wheel2021年4月16日 Grinding hand tools A die grinder is a highspeed rotary tool that is typically powered by compressed air The tool has a smalldiameter abrasive bit that rotates to get the job done Check out Choosing the Right Air Die Grinder for more information and some recommended models Angle grinders are also abrasive hand tools Unlike die grinders, Intro to Grinding Methods, Machines and ToolsThe Knifegrinder by Goya shows a man using a portable grindstone A grindstone, also known as grinding stone, is a sharpening stone used for grinding or sharpening ferrous tools, used since ancient times Tools are sharpened by the stone's abrasive qualities that remove material from the tool through friction in order to create a fine edgeGrindstone WikipediaMyth No 2: Many portable grinding/sanding machines and grinding wheels on the market are safe to use together as long as you can get the grinding wheel on the machine Fact: Failure to select the proper grinding wheel for the machine you’re using is a major cause of grinding wheel breakage and injuryGrinding wheels, rocks, stones what's the difference?

.jpg)

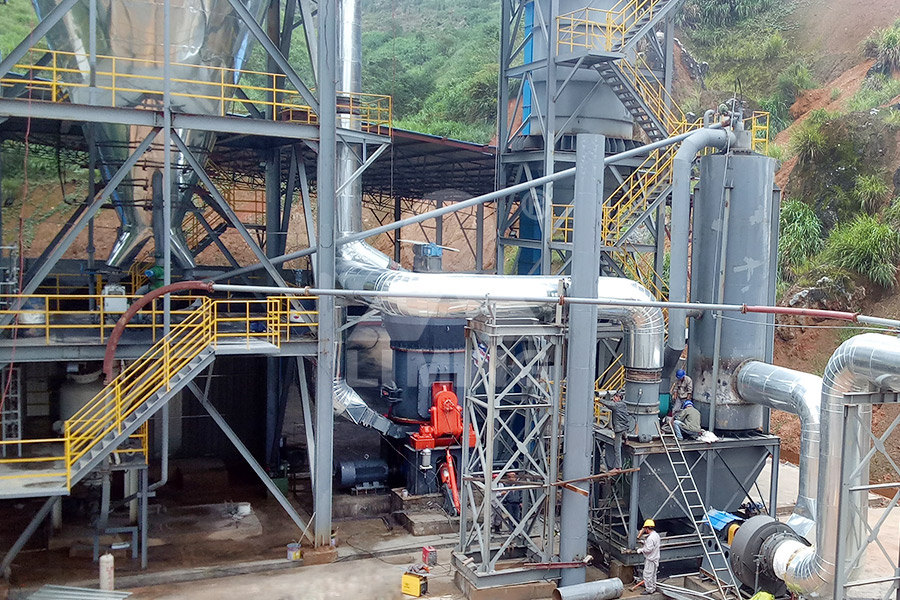

Stone Crushing Machine What is a Stone Crushing

Stone crushing machine is an industrial plant used to break large pieces of rock into smaller pieces There are many models of this industrial machine with different capacities Stone crushing is a very important process for 2007年7月30日 The grinding heads are specially designed to grind points, stock rails, frogs and close to guard rails Grinding is effective from 075 degrees gauge side and 045 degrees field side of the rail A range of different size grinding Regular grinding is the key to long rail lifeSpecification for 8stone Rail Grinding Machine 141215 1 General 11 These specifications provide the technical requirements for the manufacture, supply, testing, commissioning, maintenance and operation of a selfpropelled railgrinding machine of minimum 8 stones module (here after referred as machine) for use on theSpecification for 8stone Rail Grinding Machine 1412 Indian There are different types of grinding machines, each with its own unique set of wheels and abrasives The most common type of grinding machine is the surface grinder, which is used to remove material from flat surfaces Another common type of grinding machine is the cylindrical grinder, which is used to remove material from cylindrical surfacesWhat is Grinding? – Working Principles, Applications Use of

.jpg)

Types of machines used in rock breaking for mining ore

This process is extremely fast, but it can also be very dangerous if not used properly Types of Machines Used in Rock Breaking for Mining Ore In the mining industry, there are a variety of different machines used to break down rocks These machines can be broken down into three main categories: hammering, crushing, and drilling2015年4月9日 Grinding mills are size reductions machines that often follow crushers in the processes where finer products are desired after crushing Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills Because of the name, verb milling is also been used as a synonym for grindingGrinding Mills and Their Types – IspatGuru2020年5月19日 A grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool Each grain of abrasive on the wheel's surface cuts a Market Prospects What Is A Grinding Machine? How Should The Study with Quizlet and memorize flashcards containing terms like What wheel shapes are commonly used for surface and cylindrical grinding?, What abrasive is commonly used to grind steels?, What abrasive is used to grind nonferrous metals, cast Machine process section 7 unit 2 Flashcards Quizlet

.jpg)

What is Grinding Process How It Works Different Types of Grinding

2022年11月28日 If the grinding wheel is trimmed into a formed surface, the cutin grinding method can be used to machine the formed outer surface 2) Internal grinding It is mainly used for grinding cylindrical holes, tapered holes, and hole end surfaces of workpieces on an internal grinder, universal cylindrical grinder, and coordinate grinder2020年3月18日 What you use to dress the wheel is entirely dependent on whether the grinding wheel needs to be trued or dressed, the required cycle time, as well as several other factors The types of dressing tools include stationary What is Dressing and Why Does Your Grinding 2019年11月11日 However, it can also be used on bridge piers and river walls Limestone: A sedimentary rock and the most commonly used rock type for crushed stone in the United States One of the most versatile rocks for The Complete Guide to Crushed Stone and GravelTool Grinding – Types and Applications of Tool Grinding What is Tool Grinding: Tool Grinding is the process of using a milling machine to remove material from one or more surfaces in order to create new surfaces that are similar but not What Is Tool Grinding? Types and Applications of Tool

.jpg)

Rock Crushers Pulverizers Williams Crusher

Typically, a hopper is used to hold and feed the rock to the mill The rock is either gravity fed or a conveyor is used to feed the crusher Once in the crusher, the material is broken down using a breaker plate and grinding chamber The reduced rock exits the crusher via a conveyor belt or is discharged into a hopper2023年7月11日 In conclusion, a grain mill is a machine used for grinding grains into flour or meal It has been used for thousands of years to process different types of grains, including wheat, corn, rice, and oats Grain mills have evolved over time, from simple handoperated devices to sophisticated machines that use electricity and advanced technologiesWhat is a grain mill? A beginner’s guide to grinding your own flourPage 3 of 41 27 The Machine shall have a desirable wheel diameter of 860 mm or more (new wheel profile) However, lesser diameter up to 570 mm for Rail Grinding machine (new wheelFinal Draft Specification for 8stone Rail Grinding Machine Grinding and polishing machines for Stone, Marble, and Granite Floors: Characteristics and Differences Floor grinders play a crucial role in finishing processes for marble and granite floors They are highly versatile, used not only for these materials but also for concrete, Venetian terrazzo, and similar surfacesFloor Grinding and Polishing Machine: How to Choose the Right

Used Stone Grinding Mills for sale Fryma equipment more

Flour Matcha Stone Grinding Mill Machine Commercial Used Stone Mill new Manufacturer: Pasen; Products Description Stone Mill Machine The stone mill machine uses highquality granite stone, also called sesame stone, the motor uses highquality copper wire, the body steel is made of foodgrade 304 stainles2024年4月13日 Additionally, grinding the concrete surface can expose the aggregate, resulting in a decorative effect that enhances the appearance of the concrete Lastly, a concrete grinder grinding machine can be used to flatten uneven surfaces, such as high spots or uneven slabs, ensuring a level and stable base for further construction or installationThe Ultimate Guide To Using A Concrete Grinder Grinding MachineTypes of grinding Machine Grinding machines according to quality of surface finish, may be classified as 1 Rough /Nonprecision grinding 2 Precision grinding Rough/Nonprecision grinding To remove more stock than other grinding a)Floor stand and bench grinders (b)Portable and flexible shaft grinders (c)Swing frame grinders (d)Abrasive belt Grinding and Grinding Machine JECRC Foundation2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel 14 Types of Grinding Machines [Working, Diagram

Specification for 8stone Rail Grinding Machine (Specification

and remove corrugations The Rail Grinding Machine shall be able to effectively grind Kolkata Metro KMRCL track of Indian Railways for both Broad and Standard Gauge The supplier shall furnish all details and itemized cast about deliver, warranty, operation and maintenance including the 8Stone RailGrinding Machine as per these 2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to Quartz Processing Mastering the Art of Stone to 2024年1月11日 Surface grinding can produce various finishes on flat surfaces, from rough to mirrorlike The finishing process on a surface grinding machine depends heavily on the type of grinding wheel used – straight wheels for flat surfaces, recessed surfaces, and wheel face grinding for more intricate profilesSurface Grinding: A Guide to the Process and Precision okdor2024年1月8日 CNC grinding machines offer the highest level of precision and automation They are capable of achieving complex grinding geometries and maintaining consistent grinding results However, they can be expensive and may require specialized training to operate Importance of Choosing the Right Grinding Wheel The grinding wheel is the primary tool The Ultimate Guide to Carbide Tool Grinding

The 7 Factors Used to Determine a Grinding Wheel Specification

2021年6月18日 The seventh and final factor to consider is horsepower We have to consider the horsepower of the grinding machine to determine the grade of the bond or hardness of the wheel High Horsepower – When a machine has a higher horse power available at the spindle, we should use a harder wheel gradekota stone kota stone flooring is the best natural stone flooring Kota stone is a type of blue and brown limestone used in flooring and wall cladding, this stone is stronger than marble, Kotta stone is known from two names – first – Rajasthan Kotah and second – Tandoor cota stone, Rajasthan Kota is of better quality than Tandur Kota, k otta stone is worldfamous for its long shine and Kota Stone (Kota Pathar): Durable and Versatile Natural Stone2013年1月1日 Coverage includes abrasives and superabrasives, wheel design, dressing technology, machine accuracy and productivity, machine design, highspeed grinding technology, cost optimization, ultra Principles of Modern Grinding Technology ResearchGate2024年3月20日 Construction and Sculpting: Grinding stones are also used in construction for smoothing surfaces and in sculpting for detailed work on stone and metal Jewelry Making: Critical for shaping and polishing precious stones and metals, contributing to the beauty and value of the finished piecesGrinding Stone: The Backbone of Precision Manufacturing

How To Use A Grinding Wheel: A Comprehensive Guide

2024年8月8日 The cup wheel is a type of grinding wheel used for surface grinding It is designed for use with a horizontal or vertical spindle grinder and is available in various sizes and grits The cup wheel is usually employed for smooth surface grinding Cutting Wheel The cutting wheel is a grinding wheel used for cutting