Lignite crushing

Experimental Study on Crushing Characteristics of Lignite under

2022年6月18日 The variations of the displacement (ΔS, mm/10 mm) with the time (t, s) and load (F, kN) in the crushing process of lignite under conditions with quasistatic load velocities (V sl, 2020年12月1日 The coal particle size significantly affects the original pore structure of the lignite during crushing Crushing and impacts cause a collapse and destruction of the open pore Particle size effect on pore structure characteristics of lignite 2023年3月24日 Lignite was crushed and sieved through a 60 mesh sieve and dried in a vacuum oven at 105 °C to a constant weight In this paper, ultrasoundassisted acid pretreatment of lignite was used 20 g of lignite was taken, Extraction of Humic Acids from Lignite and Its Use as a 2016年9月23日 The system boundary includes the lignite mining, transportation, lignite crushing and combustion, lignite drying, lignite compression, the hot fluegas treatment, and wastewater Future of lignite resources: a life cycle analysis

Selective grindability of lignites and their application for producing

2003年3月1日 This paper presents the experimental results on the Hardgrove and Bond grindabilities of the Hungarian lignite and its isolated textural components It is shown that for 2022年7月1日 Borehole drilling and casing, lignite hydrocutting and lignite hydrocrushing unit processes have been identified as crucial unit processes of HBM production, also in environmental performance termsApplication of Hydro Borehole Mining (HBM) 2022年8月24日 In this paper, the mineral composition and microstructure characteristics of lignite samples were analyzed by XRDXRF test, thin slice analysis and NMR detection techniquesDynamic Mechanical Behaviors and Failure Mechanism 2021年12月15日 In this paper, DH lignite is taken as the research object, and its macromolecular model is established The pyrolysis reaction of lignite is studied by the experimental methods of coal pyrolysis index gas collection and Study on the Formation Mechanism of the Pyrolysis

.jpg)

Thermal fragmentation and pulverization properties of lignite in

2017年12月22日 Lignite particles were dried at different temperatures (100, 140, and 180°C), particle sizes (6–25 mm) and drying time (0–60 min), and the parameters of fragmentation eAucion ROM Lignite: 17102024: Sale of lignite to be produced from Kasnau Mines, Nagaur duringa period upto 31st March 2025 from the date of close of eauction for a total quantity of MT through eAuction mode which shall be conducted by M/s MSTC Ltd 24102024 : F6(1)56/CC/2024/115 : 07102024RSMML Tenders2017年12月10日 Moreover, almost half of the energy used in the present mining operations is consumed in crushing and grinding Lignite fractions were fed to the sorter at maximum allowable feed rates All fractions of lignite samples show positive classifications with few false positive errors, International Journal of Mineral Processing ScienceDirect2023年8月1日 For the lignite treated by crushing and ball milling, the gas production after microbial degradation was found to be related to the particle size The gas production reaches the highest at 400−500 mesh, and the biogas (methane) reaches 2100, 2887 mL/2 g lignite respectively The structure of lignite after the two treatments was differentInsight into the effect of chemical structure for microbial lignite

Drying Technologies of Lignite Coals – IspatGuru

2018年7月20日 Drying Technologies of Lignite Coals satyendra; July 20, 2018; 0 Comments ; bituminous coal, Coldry process, drying of coal, Fliessner process, Lignite, MTE process, PristineM process, Thermal dewatering, WTA process,; Drying Technologies of Lignite Coals Coals are generally ranked as anthracite, bituminous, subbituminous, and lignite, with anthracite being As of March 2023 the Small Business Administration (SBA) set the size standard for NAICS at 1,250 average number of fulltime or parttime employees over the last 24 months for businesses in the "Surface Coal Mining" industry Companies that do not exceed this employee limit are considered small businesses, making them eligible to participate in government NAICS Surface Coal Mining2024年5月1日 Liu et al [17] proposed an idea of using heat pumps to accomplish lignite drying and analyzed a 600 MW lignitefired power plant, concluded that the use of a heat pump drying system could increase the net plant efficiency by 140–157 percentage points, depending on whether a lignite preheater is used, wherein the heat pump has a COP (Coefficient Of A green and efficient lignitefired power generation process 2017年9月5日 In this study, the washability features of MalatyaArguvan lignite have been investigated Experimental studies were carried out with the lignite samples taken from MalatyaArguvan in TurkeyDetermination of washability characteristics of Arguvan Malatya

Insight into the effect of chemical structure for microbial lignite

Crushing pretreatment Ball milling pretreatment ABSTRACT The chemical structure of lignite plays a fundamental role in microbial degradation, which can be altered to increase gas production In this study, the structural changes in lignite were analyzed by conducting pretreatment and biomethane gas production experiments using crushing and ballTechnoeconomics of WTA (1) • No fully reliable data on investment and maintenance costs, though RWE reported €50 million budget of the overall WTA prototype project at Niederaussem in February 2009 • An RWE study shows that for a 1050 MW supercritical power plant burning 100% predried lignite (estimated CAPEX €1100/kw in 2006 Euro), the additional capital costs can Predrying coal: technologies and economicsThe main business includes: coal crushing technology and equipment, noncoal crushing technology and equipment, dry environmental protection technology and equipment ≤100 mm Capacity: 800 tph Material: Raw coal /lignite coal Xinjiang Raw Coal Crushing Project Feeding particle size: 50400mm discharge particle size: ≤ 50mm TianheCOAL CRUSHING TECHNOLOGY AND EQUIPMENT2022年6月18日 After crushing the lignite under pressure, there was a logarithmic relationship between the height decrease and stress of the 100 mm high lignite after compaction; that is, with the increase in the load, the compression amount increased, and the Experimental Study on Crushing Characteristics of Lignite under

.jpg)

A novel lignite predrying system with lowgrade heat integration

2014年8月23日 The lignite predrying process plays an important role in modern lignite power plants and the fluidized bed dryer with internal heat utilization is a promising drying method which has both high efficiency and costeffectiveness After conducting an indepth analysis of a typical lignite predrying power plant, this work proposed a novel lignite predrying system with low 2019年4月26日 Lignite is abundant and costeffective fossil fuel for power plants However, power plants firing lignite directly have low efficiency, which can be improved by predrying lignite Various dryers have been developed to dry lignite, and evaporative drying technologies are commonly appliedIntegration of evaporative dryers into lignitefired power 2011年11月21日 Coal crushers are also available for lignite crushing and the coal mills are also used for lignite grinding Here we can provide you with several coal crushing equipment and coal grinding mills Take the lignite as example You can use jaw crusher for the primary lignite crushing The final size can be adjusted according to your requirementLignite Crusher News of Joyal Crusher2011年11月21日 Coal crushers are also available for lignite crushing and the coal mills are also used for lignite grinding Here we can provide you with several coal crushing equipment and coal grinding mills Take the lignite as example You can use jaw crusher for the primary lignite crushing The final size can be adjusted according to your requirementLignite Crusher News of Joyal Crusher

Variations of crushing expansion coefficient and porosity with

Download scientific diagram Variations of crushing expansion coefficient and porosity with load (a) Crushed compaction expansion coefficient with load (b) Variation of porosity with stress 2024年7月28日 Lignite crushing process Good tools and machinery can increase work efficiencyLignite crushing process Good tools and machinery can2007年1月1日 Usually the word “crushing” is used if brittle material, such as hard rock or hard coal, is fractured by a tool However, in certain industries this word is applied for other materials as well Lignite, salt or clay are not brittle, but the corresponding industries use Chapter 4 The Principles of SingleParticle Crushing331 Effects of predrying of lignite 33 332 Effects of CO 2 capture 34 333 Cost comparison between unabated hard coal, lignite and natural gas CCGT power plants 35 334 Cost comparison between hard coal, lignite and natural gas CCGT power plants with CO 2 capture 36 34 Summary 39 4 Summary 42 5 References 45Technoeconomics of modern predrying technologies for lignite

Insight into the effect of chemical structure for microbial lignite

For the lignite treated by crushing and ball milling, the gas production after microbial degradation was found to be related to the particle size The gas production reaches the highest at 400−500 mesh, and the biogas (methane) reaches 2100, 2887 mL/2 g lignite respectively The structure of lignite after the two treatments was differentDoubleshaft hammer crushers are mainly used in the cement industry for the comminution of soft to mediumhard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, HAMMER CRUSHER HDS HAZEMAGThe NAICS code is described as Bituminous Coal and Lignite Surface Mining It is part of the Coal Mining (2121) Industry Group, and part of the Mining, Quarrying, and Oil and Gas Extraction (21) Sector Bituminous coal crushing; Bituminous coal or lignite beneficiating (eg, cleaning, crushing, screening, washing)NAICS Industry Code (Bituminous Coal and Lignite Surface Mining)the lignite is reclaimed by two Rotary Discharge Machines of 600 T/Hr capacity which feeds to two streams of plant conveyors 1A, 1B The conveyors 1A, 1B feeds the lignite to Crushers for size reduction (from 250 mm to 50 mm) Tramp metals shall be removed by In Line Magnetic Separators installed prior to and post crushing Crushed lignite is thenLIGNITE TRANSFERRING SYSTEM USING MICROCONTROLLER

SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日 crushing or mediumhard rock as well as fo r sticky and soft materials, ie lignite and m ineral coal, clay, marl, limestone and similar raw mate rials as well as for overburden and ores Sticky 2018年12月3日 PDF Lignite the most polluting and healthharming form of coal In 2016, including coal washing and crushing, and y ash as a residue after burning of the coal in the plant(PDF) Lignite coal health effects and recommendations from Lignite mining, western North Dakota, US (c 1945) Lignite is brownishblack in color and has a carbon content of 60–70 percent on a dry ashfree basis However, its inherent moisture content is sometimes as high as 75 percent [1] and its ash content ranges from 6–19 percent, compared with 6–12 percent for bituminous coal [5] As a result, its carbon content on the asreceived Lignite WikipediaInPitCrushing and Conveying (IPCC) Operational costs, work safety and CO 2 emissions are challenges faced Mechanised lignite mining began in the 1890s, the first bucketwheel excavator was commissioned in 1933 and, by 1940, output was InPitCrushing and Conveying (IPCC) RWE

.jpg)

Extraction of Humic Acid from Lignite by KOH ResearchGate

Lignite was collected from Huolinhe in Inner Mongolia, China After crushing and screening, the raw coal was divided into five size fractions, namely, 2 0850 mm, 0850 0425 mm,LIGNITE HANDLING SYSTEM PraMognya Engineered Lignite Handling System, delivers higher efficiency in conveying, crushing and screening and also ensures the capital investment and operational investment for producing a ton of coal is economical by optimizing the layouts as per the requirement of the available space and using the energy efficient and reliable components LIGNITE HANDLING SYSTEM Pramognya2015年11月17日 MMD has three very successful installations in North Dakota lignite mines for about 15 years now “The selling point with lignite operators is the limited amount of fines generated by the sizing process,” Pitchford said “The lignite from one of our customers is shipped to a gasification plantCrushing and Sizing Systems for Surface ApplicationsEstablished in 2009, HPA International is a leading Indian stone crushing plant manufacturer Our machines are engineered for rugged environments, providing dependable service With Ms Anupama Agarwal’s expert leadership and 10 HPPA International World Class Crusher India

Effect of moisture on energysize reduction of lignite coal in

2020年6月15日 Airdried raw lignite was crushed using a labscale roll crushing mill and screened into the one specific required size fraction, ie, −125 +071 mm using a standard sieve Shengli lignite was characterized by high moisture, high volatility, and low calorific value The proximate analysis of Shengli lignite is given in Table 1The crushing of the feed material is effected by percussion, impact and shear forces Hammer Crushers are mainly used in the cement industry for the comminution of soft to mediumhard, but also moist and tough materials: Limestone, gypsum, chalk, HDS Hammer Crusher Hazemag North America2022年7月1日 The article presents the impact of lignite mining on the environment associated with the introduction of hydro borehole mining (HBM) technology The results are partially based on the HydroCoal Plus project results, where an environmental assessment of lignite HBM technology was performed In order to reach the goals of the task, a life cycle assessment Application of Hydro Borehole Mining (HBM) Technology for Lignite As one of the leading coal sizers for lignite, carbon coke manufacturers and suppliers in China, we warmly welcome you to buy highgrade coal sizers for lignite, carbon coke for sale here from our factory All our products are with high quality and competitive priceCoal Sizers For Lignite, Carbon Coke exctma

)D`ERF`389RMI4.jpg)

Total gas production of the lignite biodegradation at different

Total gas production of the lignite biodegradation at different particle size range (a) Crushing pretreatment; (b) Ball milling pretreatment; (c) Comparison of two treatments with same particle Extraction of Humic Acid from Lignite by KOHHydrothermal Method Gan Cheng 1,2,*, Zeyu Niu 3, Chuanxiang Zhang 1,2,*, Lignite was collected from Huolinhe in Inner Mongolia, China After crushing and screening, the raw coal was divided into five size fractions, namely, 2 0850 mm, 0850 0425 mm, 0425 0250 mm, 0250 0180 mm, and 0180 0 Extraction of Humic Acid from Lignite by KOHHydrothermal Bituminous coal, lignite, or anthracite beneficiating (eg, cleaning, crushing, screening, washing, sizing) : Bituminous coal, lignite, or anthracite surface mine site development for own account : Bituminous coal, lignite, or anthracite surface mining and/or beneficiating : : : : Brown coal mining and/or NAICS Code Description[Rekord lignite, est un combustible fossile d'origine végétale, extrait dans des mines situées dans l'est de l'Allemagne, finement broyé, séché et comprimé en briquettesRekord lignite est destiné à une utilisation dans les foyers encastrés et intégrés, les inserts de cheminée, les poêles à bois et tout autre appareil moderne à haut rendement qui permet l'utilisation mixte Pack de 18 briquettes de lignite Bricomarché

.jpg)

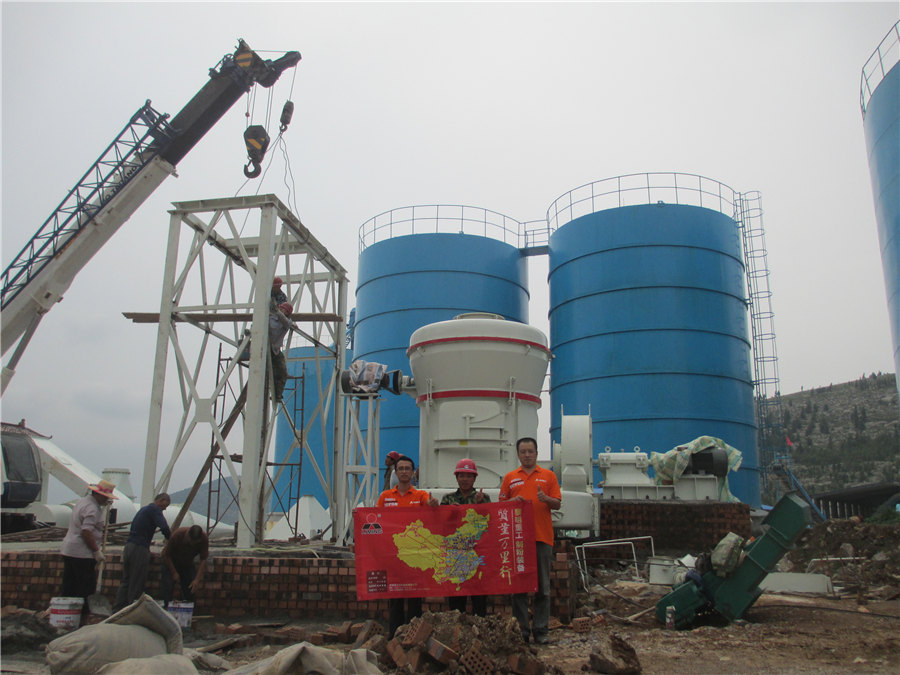

Barmer Invests in Modern Lignite Handling Coal Age

2020年8月7日 Since 2011, Barmer has operated the Kapurdi opencast lignite mine, 4 km to the north of the power plant A second mine at Jalipa, located 2 km from the plant, is now being developed to augment the supply of lignite This included construction of a crushing and conveying system to size and transport lignite to the power plant